The Benefits Of Pcbs

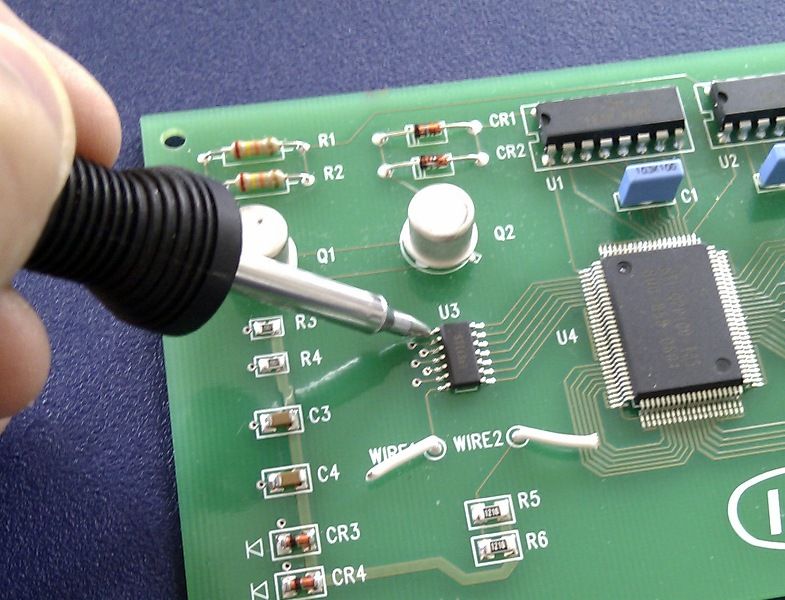

Before launching a complete production run, it is essential to verify that a printed circuit board (PCB) is operating correctly. Regardless of how attentively designers work on a project, the functionality of the finished product is always a danger from apparently little faults and problems that are not immediately apparent. If these difficulties are not detected and resolved before the beginning of full production. The overall cost of the project may rise.

1. Accelerated Rate Of Occurrence –

When creating a printed circuit board, engineers will go through several iterations before arriving at the final product (PCB). Even while this may result in lengthy timelines, the usage of PCB design prototypes may help speed up the design and manufacturing process in the following ways:

The usage of PCB prototypes allows design teams to test designs and discover defects quickly and accurately, eliminating any element of the guesswork from the process. In the absence of this, finding faults would involve much more time and effort. Resulting in a longer time frame, less money, and disgruntled customers.

Customers often like to inspect the final product at different stages of the production process. Providing clients with prototypes as visual aids may facilitate their understanding of the product’s design.

2. Manufacturing Analysis And Useful Suggestions –

When using the services of a third-party PCB design service prototyping company. Businesses have the option to benefit from the assistance of a new set of eyes. Various possible dangers might lead to mistakes throughout the design process, including the following:

An excessive quantity of feedback might render the design unrecognizable compared to its first version. Modifications requested by consumers and executed by teams might stack and overlap throughout the hardware design company process.

Design blindspots: Designers are human, and individuals have blind spots. Even if a designer is very talented in the creation of a certain kind of PCB. They may lack knowledge in other areas, which may result in the insertion of a tiny defect in the design.

Design-rule-check (DRC): Design-rule-check (DRC) techy hit tools, although being immensely valuable for identifying evident design errors, have several limitations. DRCs can verify, for instance, that a return route to the ground exists; nevertheless, they may not be able to determine the appropriate trace form, size, and length to get the best results from that path.

These worries may cause hardware design and development, to overlook inefficiencies, design flaws, and other issues throughout the review process. Third-party prototyping services are well-positioned to uncover such small flaws.

3. Precise And Dependable Prototype –

Having an accurate and reliable PCB prototype makes it much easier to correct design issues at any stage of the development process. Quality PCB prototypes accurately depict the functioning of your final product. Allowing designers to view and test aspects such as the following:

PCB design: Prototyping allows designers to detect mistakes early in the product development process. Error detection will be more accurate the more precise the design. This helps save money on design costs in the future and reduces the total time required to execute the project.

What is correct in theory about functional testing is not always relevant in practice. Accurate PCB boards will aid in examining the theoretical values of the board to evaluate whether or not they appear in the actual values of the board.

Testing in real-world conditions PCB items must undergo the essential testing to ensure. That they can resist the impacts of external conditions since the real world is such a demanding environment for products.

Prototypes aid in determining if the product or packaging must be modified to fit the final PCB design. PCBs are often included in the final product, and prototypes assist determine if this is the case.

Due to these factors, having an accurate PCB prototype will facilitate the simplification of other processes and better prepare design teams for what to expect when production runs begin.

4. Evaluate The Individual Components –

In embedded engineer, printed circuit boards (PCBs) prototypes are often used for testing. But the most relevant testing is done with miniature PCBs that evaluate individual components’ operation. These prototype printed circuit boards are used to test particular features that will be included in a larger PCB.

Using small printed circuit board (PCB) prototypes in proof-of-concept runs allows designers to examine and assess a design idea before proceeding to further phases of the design process.

Printed circuit board (PCB) prototypes are often used to identify the primary components of a completed PCB. This ensures that the design can accomplish one essential goal before moving on to the next.

Individual testing allows designers to test certain capabilities effectively and efficiently without having to acquire a whole printed circuit board (PCB) and then dismantle it to discover the cause of a failure.

5. Lessening Of Expenses –

Standard PCB production runs may get rather expensive, and if you leave anything to chance, the overall cost might skyrocket. The use of prototypes, which are essential for reducing production costs, enables designers to address and avoid the following obstacles.

Identifying mistakes in the design If the development team can spot a design flaw as soon as feasible. The issue may be resolve more rapidly and at a lesser cost. The cost of the repair will grow proportionately with the procedure’s stage at which it is identify.

Identifying modifications that will lead to cost savings: Depending on the design of the printed circuit board (PCB). There may be a variety of possibilities for the materials and components used to construct it.

The procedure for identifying product modifications in certain cases. Making alterations to the PCB will result in the PCB having a slightly different form or composition than initially intended.

- Conclusion –

Circuit board prototyping is an effective method for assessing the performance of your final product. Original equipment manufacturers (OEMs) may examine the feasibility of a PCB design and produce error-free PCBs via the fabrication of prototype PCBs. Armed with industry best practices, the organization offers a prototype solution. That is speedy, accurate, and has a low minimum order quantity.